Silage bagger EB 310 LX

The silage bagger EB 310 LX is a combination of the EB 310 LS and EB 310 LG. It is conceptually the same machine as the EB 310 LG, offering high performance, optimum speed and even filling of the bag. The indisputable advantage of this machine is the unique braking system using the inner rope.

Parameters of silage bagger EB 310 LX

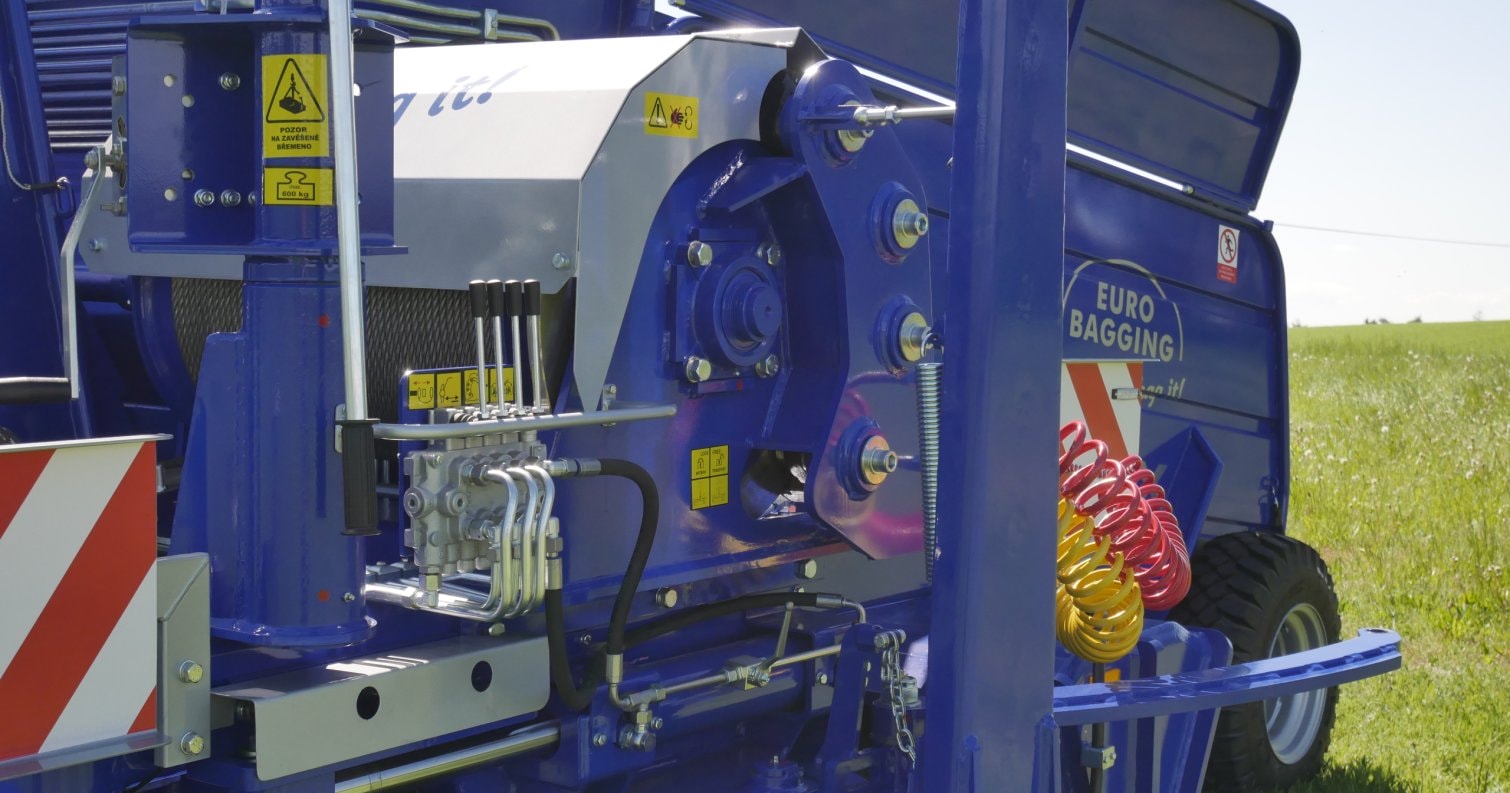

The silage bagger EB 310 LX is technically sophisticated and uses the latest accessories on the market. Its hydraulic system is adapted to LOAD SENSING with a fuel-efficient tractor. In addition, you can freely combine all 3 tunnel sizes: 2.4 + 2.7 + 3.0 m.

The EB 310 LX silage bagger has an approved speed of 40 km/h for road transport. Since it is towed on all axles, transporting behind the tractor is very comfortable even on larger unevenness.

EB 310 LX - Technical data sheet

Grass haylage

A specially designed rotor with irregular finger placement guarantees high-quality silage in the bag. It regularly compresses the feed into the pressing chamber - the tunnel, from which all the air is expelled. The machine is able to compress all kinds of grass, clover grass, alfalfa and various mixtures. In order to guarantee the quality, it is necessary to observe the correct technological harvesting procedure, especially for the correct length of the chopped material and the optimum dry matter. With the machine it is also possible to vacate haylage after self-loading wagons, but it is necessary to take care of sharpness of knives on the wagon. In general, the longer and drier the chopper is, the more difficult the compression in the bag will be and the subsequent quality of silage in the bag will decrease. Disc brakes are used to properly silage the silage, which hold the barrier at the end of the bag over the steel ropes. The EB 310 LX has 4 large brake callipers for gradual unwinding of the ropes without jumps and shocks.

Corn silage

Storing corn silage is easier than storing grass silage. Corn is loose and the bag is more regular. Lower brake pressures are also used. If you select good terrain for bagging, you can brake the machine without the rear harrow. In the case of internal braking, when a rope loop of different length passes through the bag, the wheels are braked through the air system. You control the braking rate on the control platform. With this system you can make bags longer than 75 m, most often 90 m or 120 m. Internal braking is also more comfortable, it does not need to support steel ropes, no winding ropes at the end of the bag and moving the barrier from bag to bag. We have confirmed from our customers that daily performance with internal braking is 30 % higher than bagging with the goal.