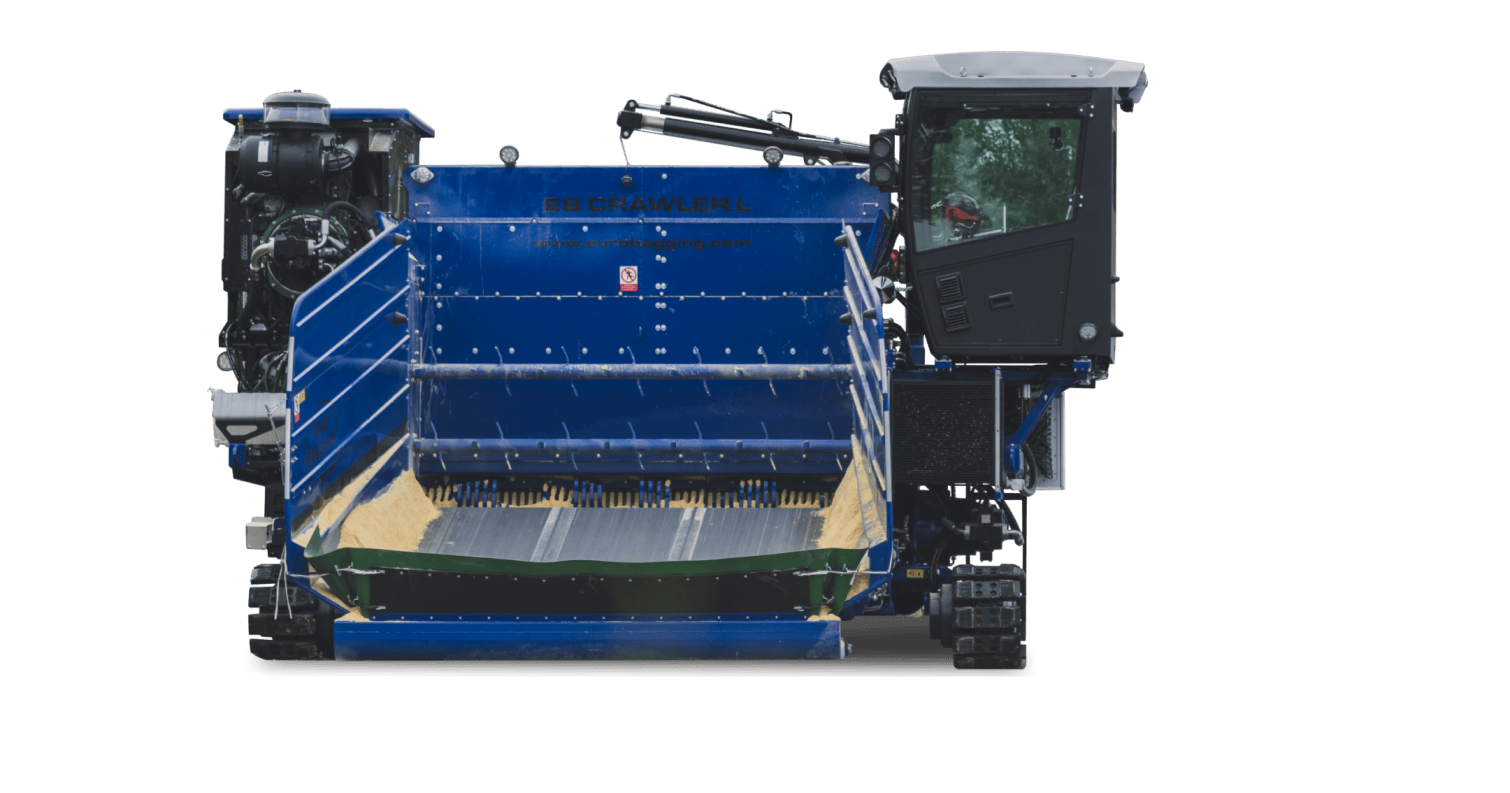

Silage Bagger EB Crawler

Innovative Silage Bagger – Efficient, Mobile, and Ready for Performance

You might be wondering what this unconventional machine is designed for. Its construction is entirely different from traditional tractor-drawn silage balers.

Parameters of silage bagger

- This self-propelled silage baler was developed at the request of several major contractors who serve a wide range of customers across large distances.Transporting a conventional baler hundreds of kilometers every day makes little sense – neither in terms of efficiency nor operating costs.

- Our new machine can simply be loaded onto a low-loader trailer, quickly unloaded at the customer’s site, and you can start filling the bag immediately.

- No lengthy setup, no complicated wheel adjustments – just attach the bag and go.

- Thanks to its tracked undercarriage, it can handle even challenging terrain and allows precise control of the braking pressure, which is key for perfect compaction of the material inside the bag.

- With this machine, there is no need to use a stop block – ever.

Video

We are currently offering the L (Large) model. Soon, we will also introduce the M (Medium) and XL (Extra Large) versions designed for large-scale operations.

👉 Want to learn more?

Contact us – we’ll be happy to present all the details and customization options to fit your specific needs.